The HiMSEN H17 / 28u (E) engine has been developed based on the intelligent himsen engine design concept, a simple, reliable series of products. This is the innovation of the H17 / 28 engine design concept, marine generator professional engine.

High power and low weight help to facilitate and save ship space.

In addition, the engine has excellent performance, low fuel consumption, low emissions and other advantages.

HiMSEN H17 / 28u (E) medium speed diesel engine in environmental protection marks the birth of a new era, with a compact structure, simple and fashionable appearance.

Technical parameter:

|

|

Company |

H17/28E |

H17/28U |

|

Cylinder number |

|

6 |

|

|

Rotational speed |

rpm |

900/1000 |

|

|

Single cylinder power |

kW |

110 |

134.2 |

|

Bore |

mm |

170 |

170 |

|

Piston running speed |

mm |

280 |

|

|

Average piston speed |

m/s |

8.4/9.3 |

|

|

Mean effective pressure |

bar |

23.1/20.8 |

28.1/25.3 |

|

Compression ratio |

- |

15:1 |

|

|

Fuel consumption |

g/kWh |

189/190 |

191 |

tolerance±5%

More environmentally friendly and advanced systems:

Air and waste gas system

H17 / 28u (E), using a high performance turbocharger, not only ensures the maximum output load efficiency, but also optimizes and simplifies the installation interface. A simple and trusted device should have fully automatic cleaning function. The standard direct air injection system ensures the high efficiency and fast response of the engine. The plenum chamber is designed to prevent pressure loss and optimum intake performance. The exhaust system is optimized according to the gas flow to ensure the maximum efficiency of the turbocharger. The design of the exhaust system is based on gas exchange kinetics, thermal expansion and so on, and it is easy to maintain.

lubrication system

The lubricating system consists of a lubricating oil module with thermostatic valve, a double oil filter, a centrifugal filter and a lubricating oil cooler. The main oil pump has a regulating valve and a pre lubrication pump. Lubricating oil flows through the engine is based on the optimization of the bearing clearance, to ensure a large margin of safety.

cooling water system

The cooling water system consists of low temperature (LT) and high temperature (HT) of the engine. The pump shell and temperature control valve shell are combined together to ensure the optimum flow and protection under various working conditions.

fuel system

The fuel system is designed for the reliable combustion of heavy oil and diesel fuels. The fuel filter module and the fuel drain alarm box are combined in the fuel filter module. This provides a convenient fuel system environment for easy access and maintenance. It also means a simplified design of appearance. High pressure block adjustment, compact structure, convenient maintenance, high performance. The optimization design of other parts of fuel system ensures low maintenance cost and convenient operation.

Engine automation

Himsen units provide the engine safety automation system, control and display based on programmable logic controller. The system is installed independently on each engine, and can also be connected with the remote control system of the main switch board of the engine control room through the cable communication cable. In addition to fulfilling the requirements of all classification societies and IACS, the system provides more friendly functions to customers.

For example,

Small size, easy to install

Digital display (engine and RPM)

Simple operation, free of maintenance

Generator Set100%Load rated output

|

Diesel engine model |

900rpm/60hz |

1000rpm/50hz |

||

|

Diesel engine |

Crew |

Diesel engine |

Crew |

|

|

6H17/28U |

805 |

750 |

805 |

750 |

|

6H17/28E |

660 |

618 |

660 |

618 |

|

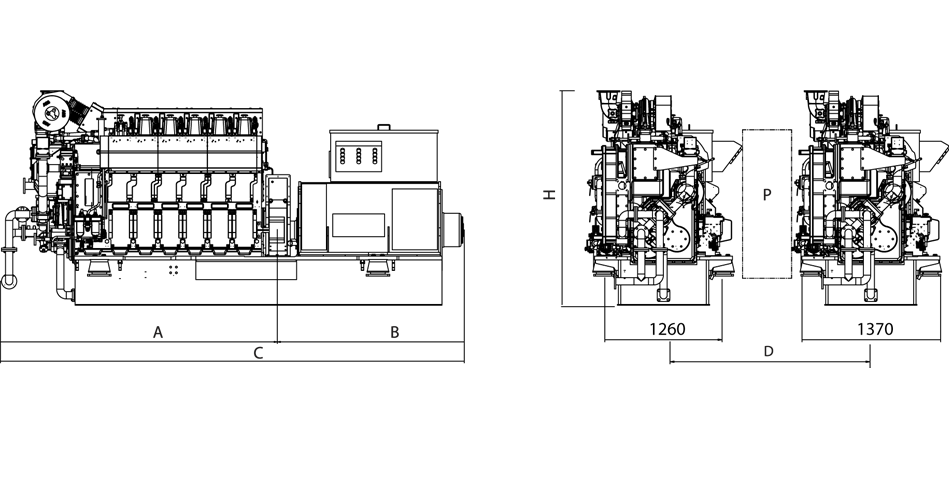

Diesel engine model |

size(mm) |

Net weight(t) |

||||

|

A |

B 1) |

C 1) |

H |

Engine 2) |

Genset 1)3) |

|

|

6H17/28U |

2744 |

2069 |

4843 |

2393 |

7.1 |

13.8 |

|

6H17/28E |

2744 |

1939 |

4713 |

2323 |

6.9 |

13.0 |